The term “thermal spray” stands for several different types of surface coatings. Thermal spray may be used for metallic and non-metallic components. Depending on the desired properties, we can coat your components with pure metals, metal alloys, oxide ceramic or carbide materials. An important advantage: The surface of the components to be coated is subjected to hardly any thermal stress (unlike in the case of deposition welding). Typical properties of a thermal spray coating are the homogeneous structure, crack free and good adhesion to the component.

Thermal spray coatings are particularly suitable for the following purposes:

- Wear protection (abrasion/adhesion)

- Protection against corrosion and oxidation

- Thermal and electrical insulation

- Targeted influencing of friction and sliding properties

How does thermal spraying work?

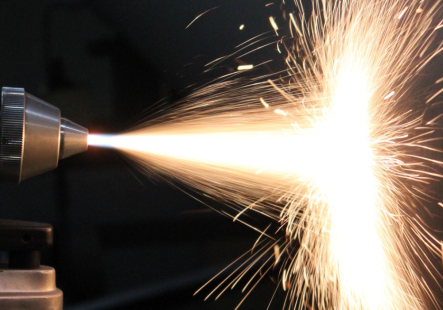

The materials (powder, wire) are melted or fused by means of a torch and are sprayed as spray particles onto the substrate surface to be coated. A relative movement between the torch and the workpiece produces the coating. Two types of energy influence their properties: thermal energy (fuel gas-oxygen, plasma, and arc) and kinetic energy (velocity of the particles).

Twice as good: Combine the advantages of 2 properties

With conventional polymer coatings, you can achieve good non-stick and sliding properties. If you also require a particularly high wear resistance, we often recommend a combination of thermal spray coating and plastic/polymer coating. The thermal spray coating serves as a metallic protective matrix (EXCALIBUR® internal link), the subsequent plastic/polymer coating as a top coat. The result unites the advantages of both systems: Wear protection/wear resistance plus non-stick and sliding properties.