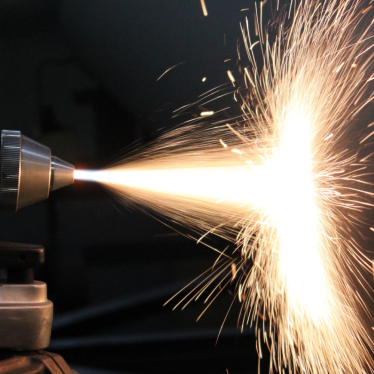

At Technicoat s.ro. we believe that efficient processes are the foundation of any successful business. Our process management approaches are designed to ensure maximum quality, performance and customer satisfaction. Continuous improvement and innovation are an important part of our strategy, allowing us to be flexible and responsive to changing market needs.

Technicoat can perform more than 10 types of pre-treatment processes on your parts,more than 10 types of functional coating processes, from robotic applications to bulk coating.

The last process is functional coating curing, and Technicoat has high capacity curing ovens for parts up to 8 meters or 5000 kg.

In this section we will introduce our key processes that enable our company to achieve exceptional results.

Let's explore together how our processes can contribute to your success!